The filter that came with the Bambu Lab X1C 3D printer is not great – to be honest it looks like it is not working at all. Recently I had to print many parts with ABS. The fumes generated from ABS smell horrible & are quite toxic ! Even when printing with PLA you can easily smell the fumes. To fix this issue I have designed this X1C Fume Filtering System.

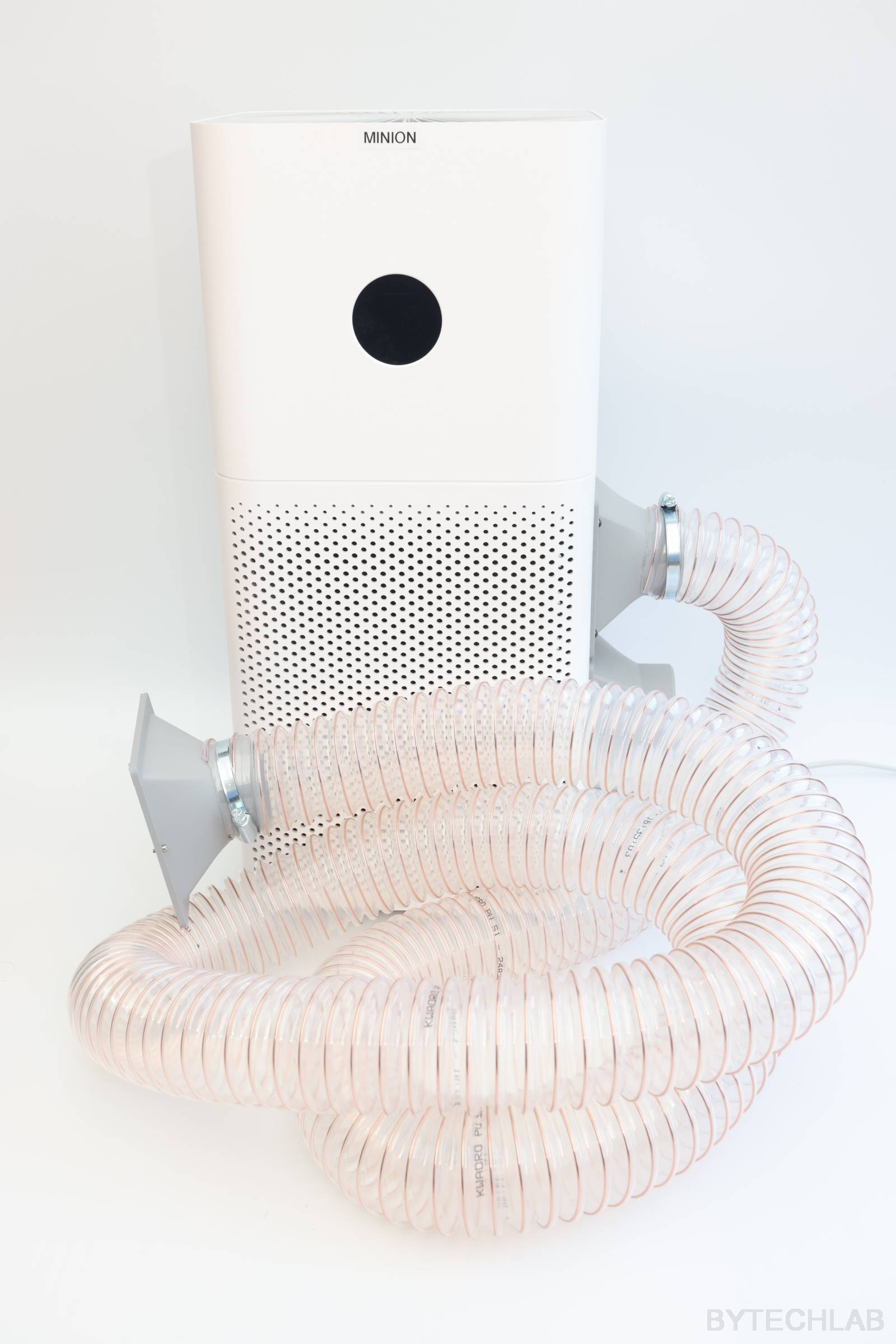

I tried to keep the whole project simple & cheap, it is built from readily available COTS parts. I have used Xiaomi Mi Air Purifier 3C air purifier to filter out the dangerous fumes ( it has multi layer filters made exactly for this purpose – PET,HEPA,CARBON ). The surface area and effectiveness of this filter is huge! It is so much better than the X1C filter.

X1C fan together with air purifier fan create a negative pressure inside the X1C printer. Because of that the toxic fumes will not escape the printer case – the only way they can go is through the hose and the through multi layer air purifier filter.

Also if the filter wears out you can easily purchase a replacement. The 3C is not available any more – you can use any other air purifier that is available on the market ( Xiaomi Smart Air Purifier 4 Lite for example ). The system is built in a way you can attach multiple printers to a single air purifier.

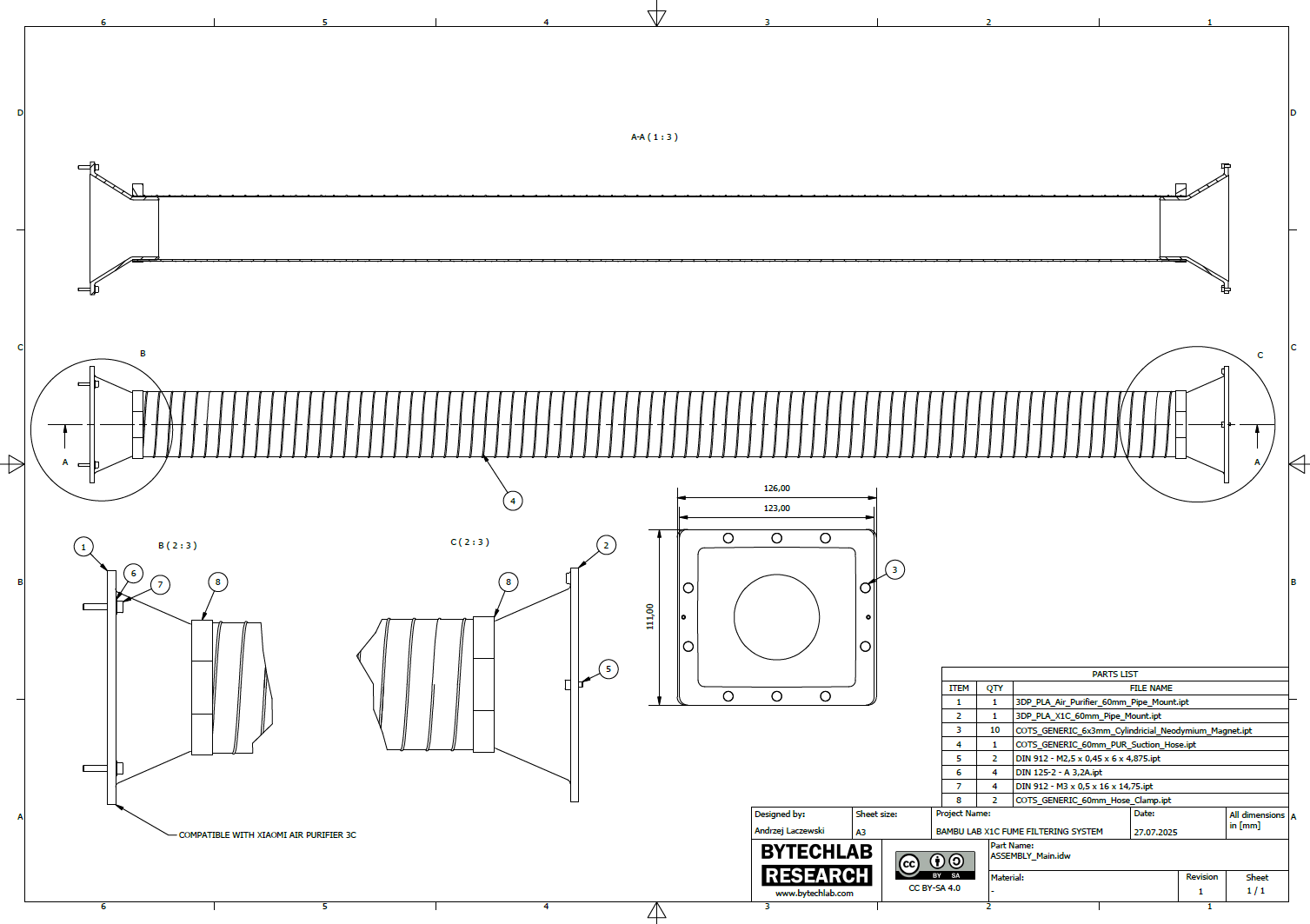

MCAD DESIGN & 3D PRINTING

Mechanical parts were designed in Autodesk Inventor. All parts were optimized for FDM 3D printing.

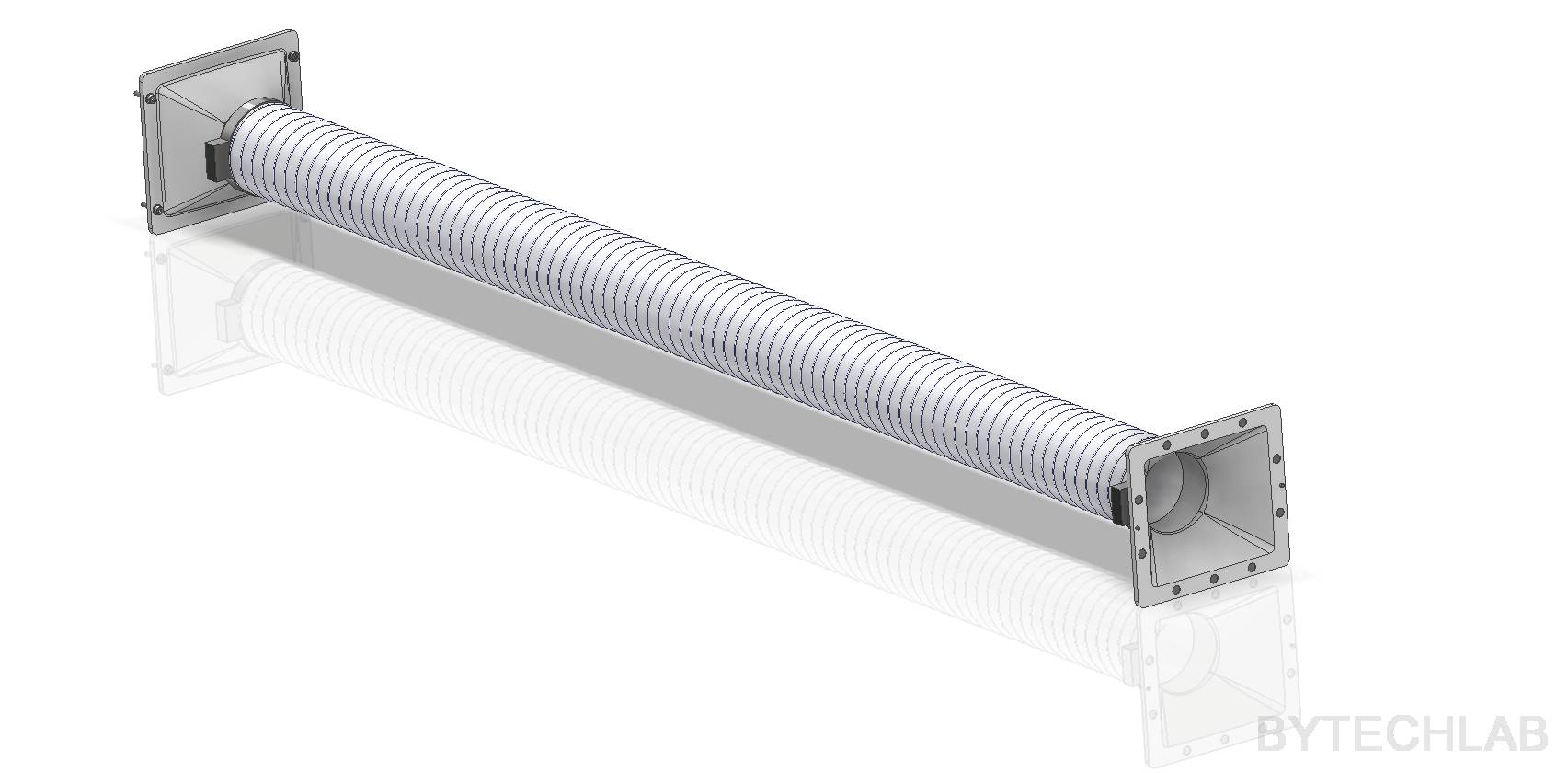

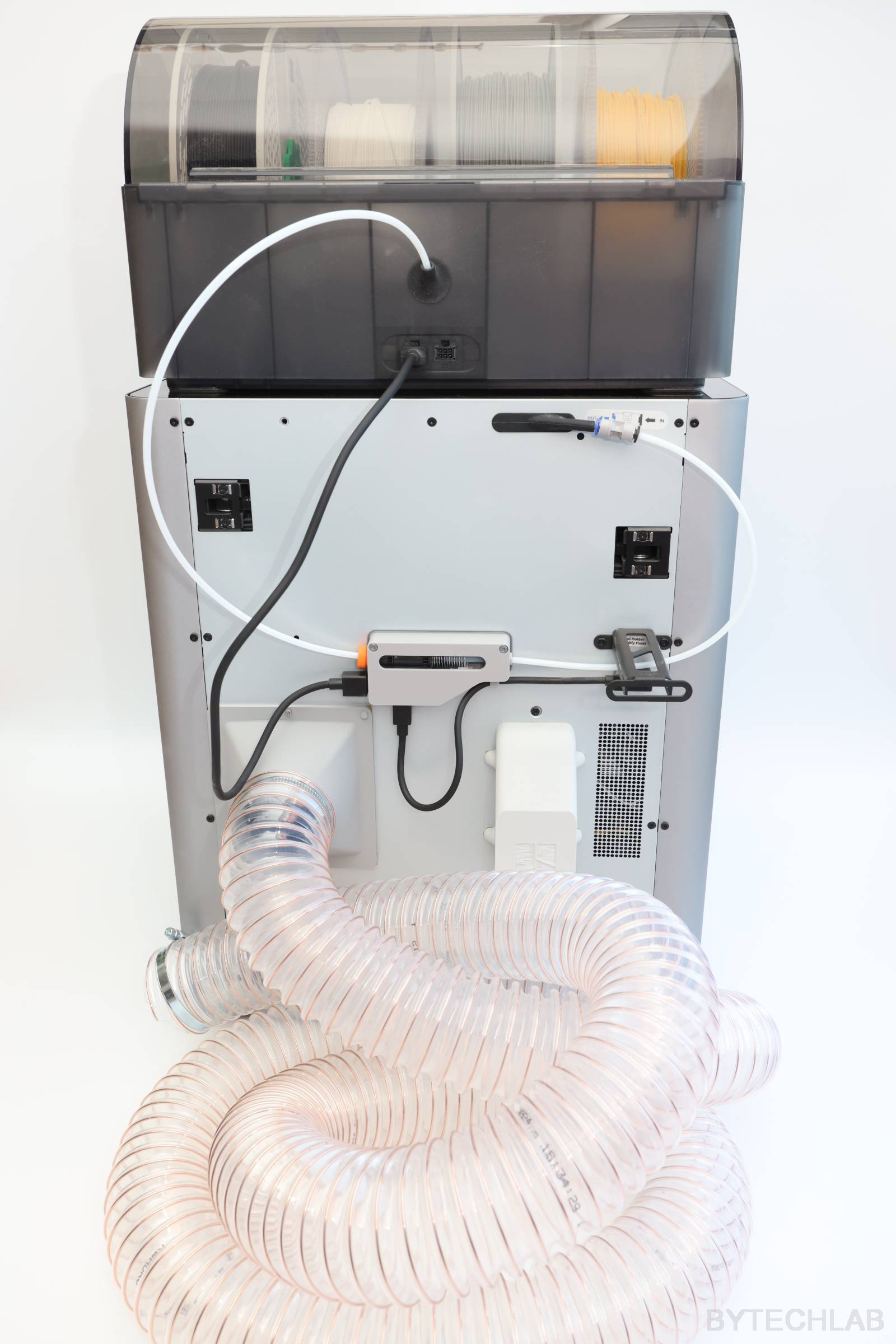

To connect the printer with the air purifier a 60 mm diameter PUR “spiral” suction hose was used. Link to similar part: https://tameson.com/products/hl-pur-l-60-antistatic-pur-pressure-and-suction-hose-60-mm-id-42-mm-br-1-m-x1 . It is very flexible and it holds its shape very well. I was able to buy 6 meter long one locally for only 25 USD.

In the GitHub repository (MCAD folder) you can find the following files:

- Autodesk Inventor project,

- Exported STL files for 3D printing,

- Exported STEP file of the whole assembly,

- Exported PDF file with assembly drawing, BOM and assembly instructions,

- Exported assembly renders,

Recommended printing settings:

- 0.2 mm layer height,

- PLA filament,

- 40 % rectilinear infill,

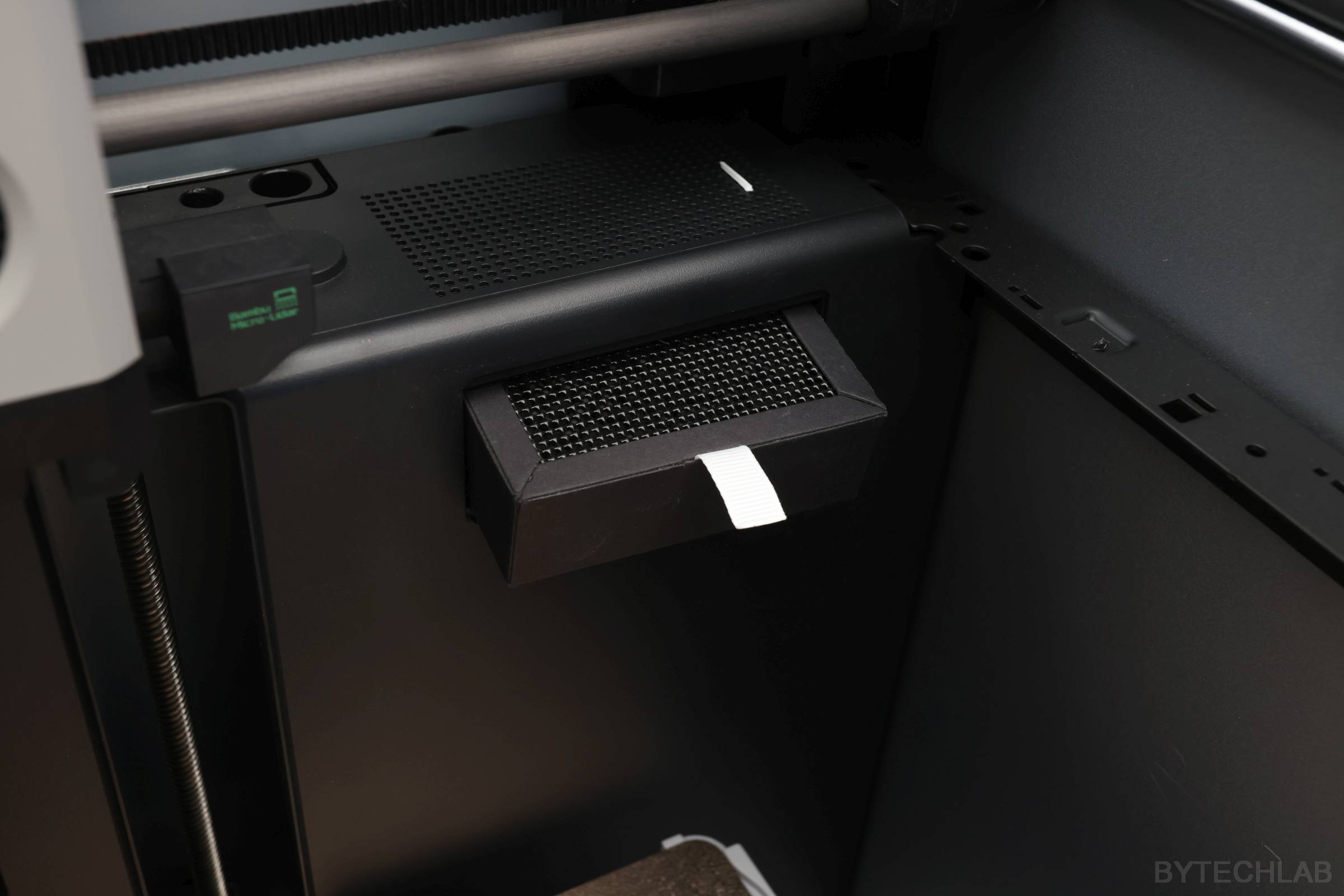

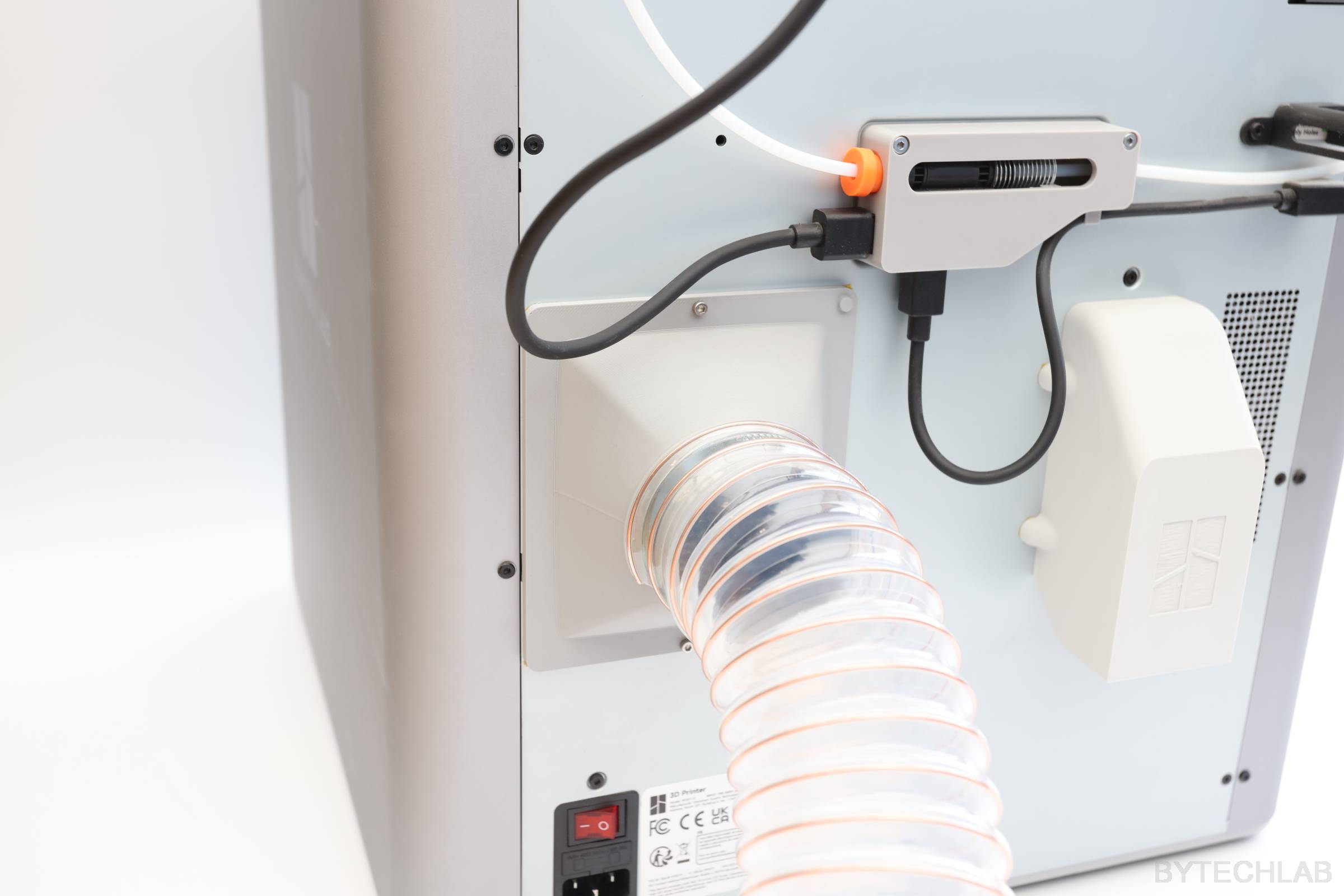

FACTORY MADE FILTER REMOVAL

The exhaust fan in the X1C is barely able to push the air through this filter. Since we want it to push the air through relatively long pipe you have to remove it to increase the air flow. This filter is not working anyway – we are not losing anything by removing it.

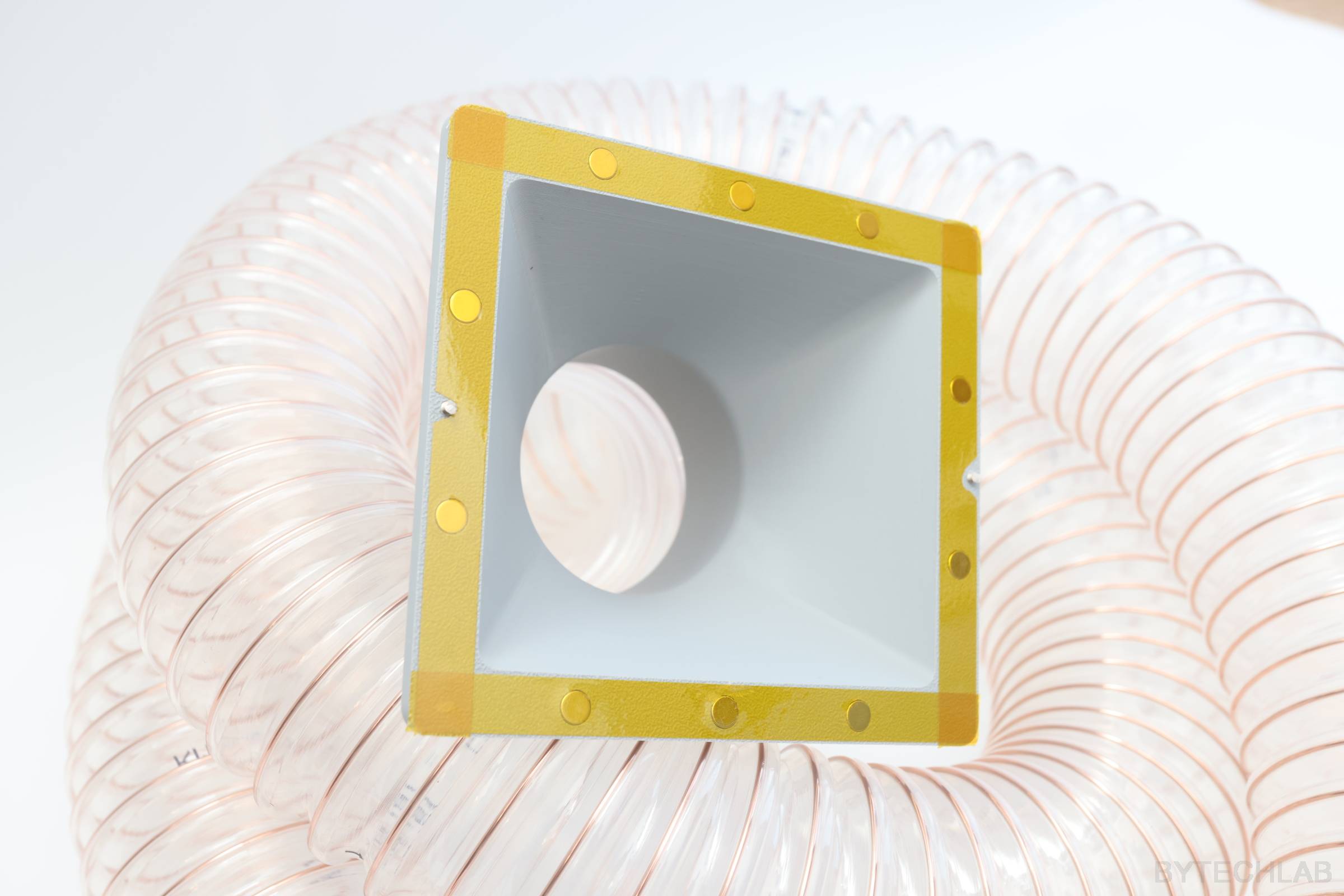

ATTACHING HOSE TO THE X1C PRINTER

The hose is attached to the Bambu Lab X1C 3D Printer with use of 3D printed “funnel” and 6×3 mm cylindrical neodymium magnets. I have also added two M2.5 screws that fit into the holes in the back of the printer to align the 3D printed part in desired spot.

ATTACHING HOSE TO THE AIR PURIFIER (Xiaomi Mi Air Purifier 3C)

To attach the hose to the air purifier I have also 3D printed some “funnels”. They are mounted to the air purifier with use of M3 screws – you don’t have to make any modifications in the air purifier – it fits to the existing ventilation holes.

Also you don’t need to seal off the rest of the holes in the air purifier case – the air flow is high enough to pull the fumes from the hose. On top of that the air purifier still is able to suck in the air from the room and filter it. So in case if some of the fumes do escape from this system the purifier will filter them out eventually.

The purifier has 4 sides – each of them can be used to mount two pipes. So in total one such air purifier can be used to handle 8 printers!

WORTH WATCHING

It is worth to watch this video recorded by Thomas Sanladerer to learn more about fumes that are generated by FDM 3D printers.

SUMMARY

I’m very satisfied with this system – there’s zero smell when I’m printing with ABS or any other filament. The PM2.5 sensor showed a value of 60 when printing with ABS in a closed room without this filtering system. When using this system the PM2.5 sensor shows the value of 0 !