In 2020 due to COVID-19 pandemic the whole world has got crazy. Airplanes stopped flying, many countries declared state of emergency, many hospitals are full of infected people and much more stuff like that. This sounds insane, doesn’t it ? Nevertheless, we have to deal with this global crisis somehow… Makers all around the world are trying to help hospitals and other people in need by designing and manufacturing some useful stuff like respirator parts , masks, face shields etc. The idea for this DIY Positive Pressure Suit came to my mind when I saw positive pressure suits in the “Contagion” movie. They are using these in labs where they handle dangerous viruses and other nasty stuff. The main problem with this suit is that it must be connected to a hose supplying filtered and compressed air which is not available outside the lab of course.

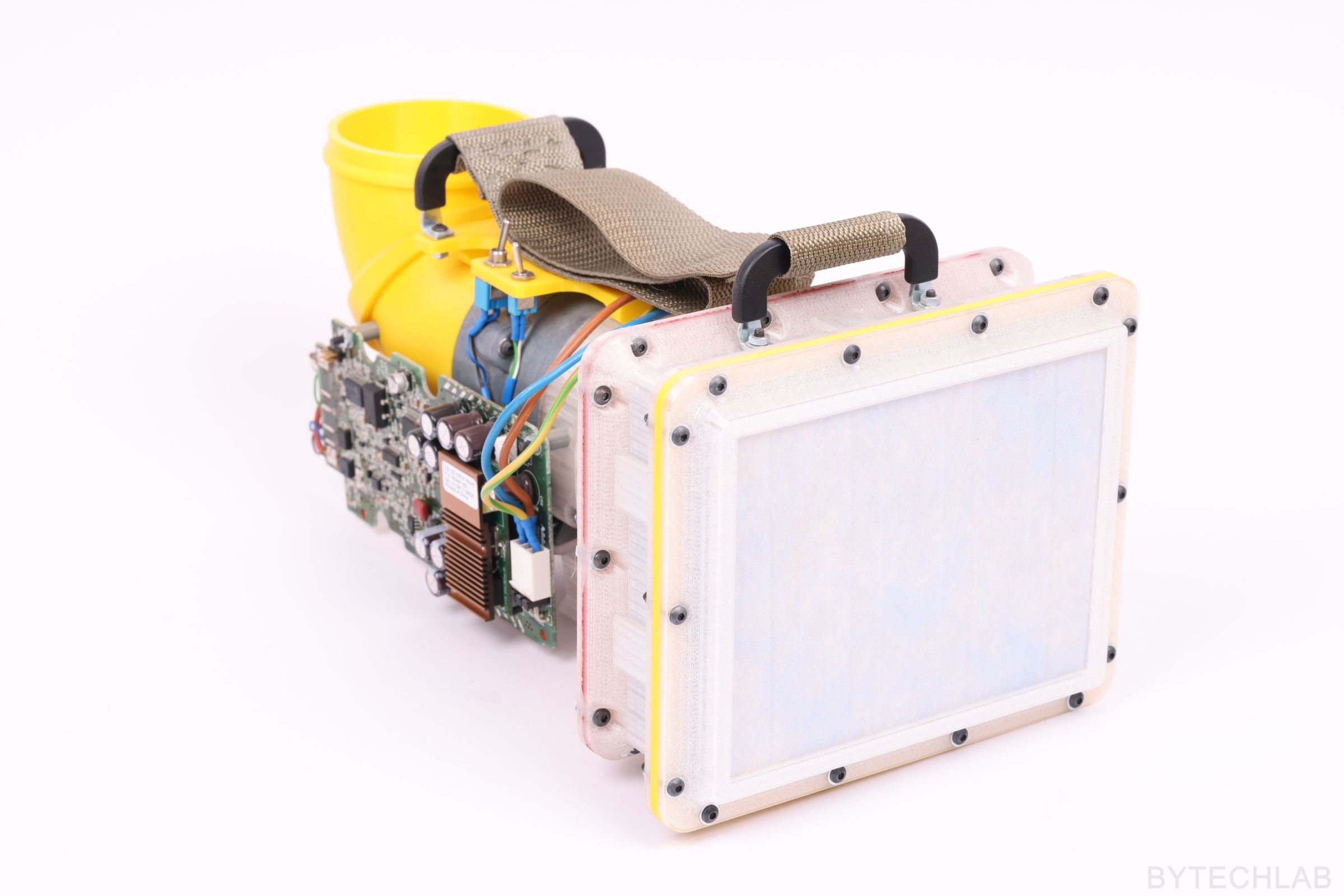

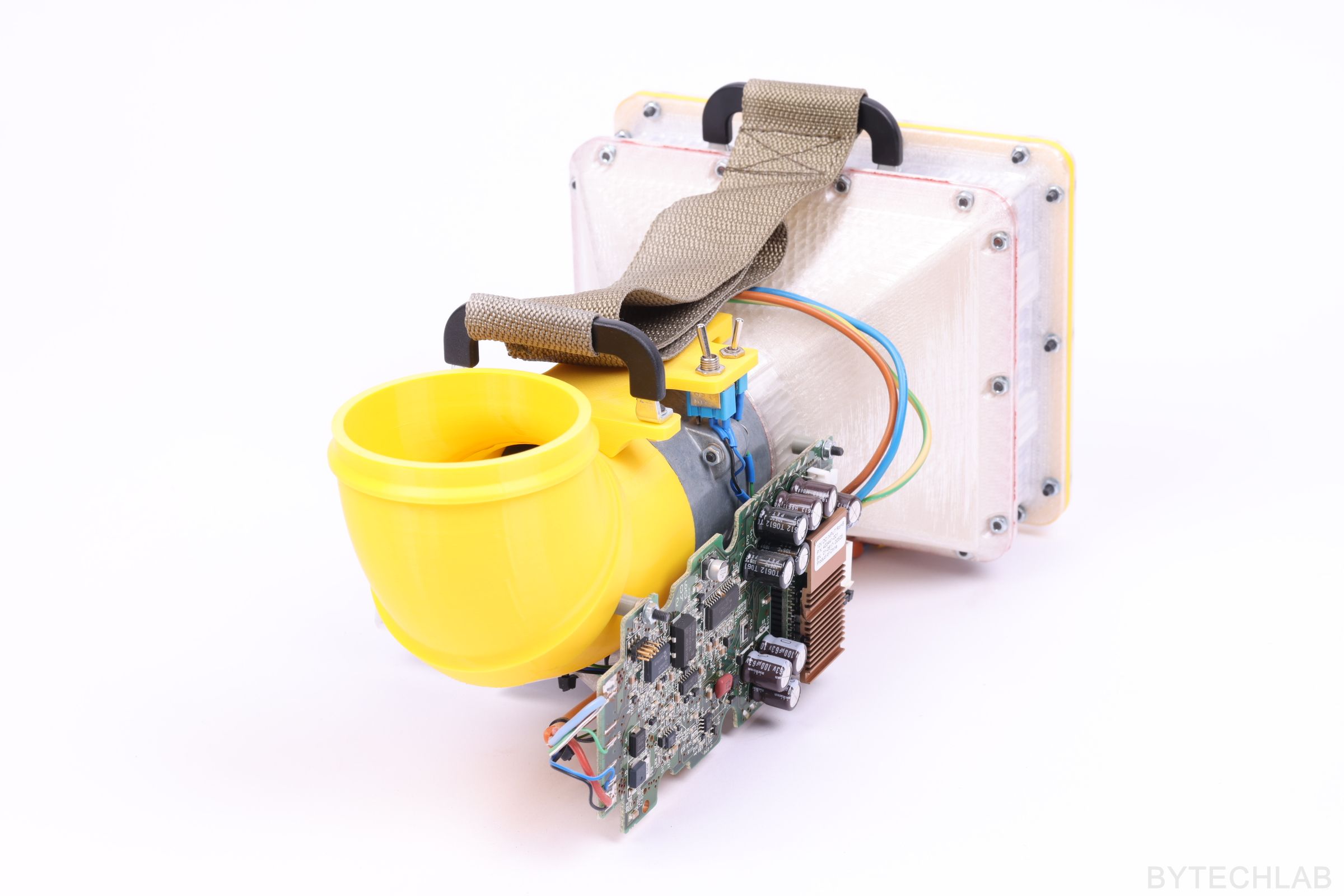

To solve this problem I’ve designed a AFU (Air Filtering Unit) which is responsible for filtering , purifying the air and pumping it into the suit. Because of the positive pressure inside ,the suit doesn’t need to be 100% air tight. Why is that? Well, the answer is quite simple – contaminated air around you will be repelled by air that is coming out from the suit. Because of that you will always breathe with a clean filtered air (assuming that filters capture every dangerous particle).

With such a suit, entering the contaminated zone should be relatively safe.

DISCLAIMER

I am not able to test this device in a scientific way. If you make and wear one of these in a hazardous situation you will be doing it at your own risk!

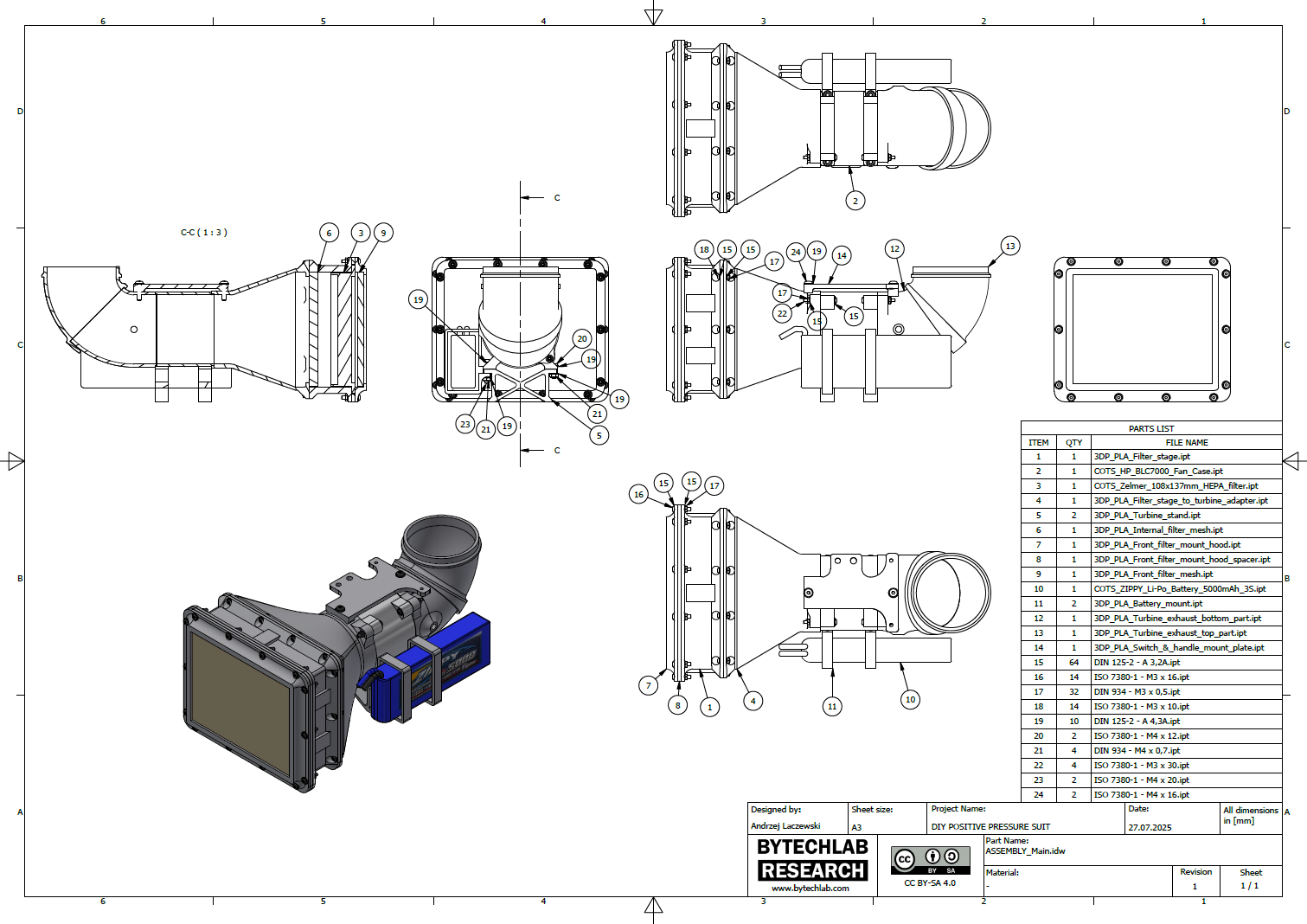

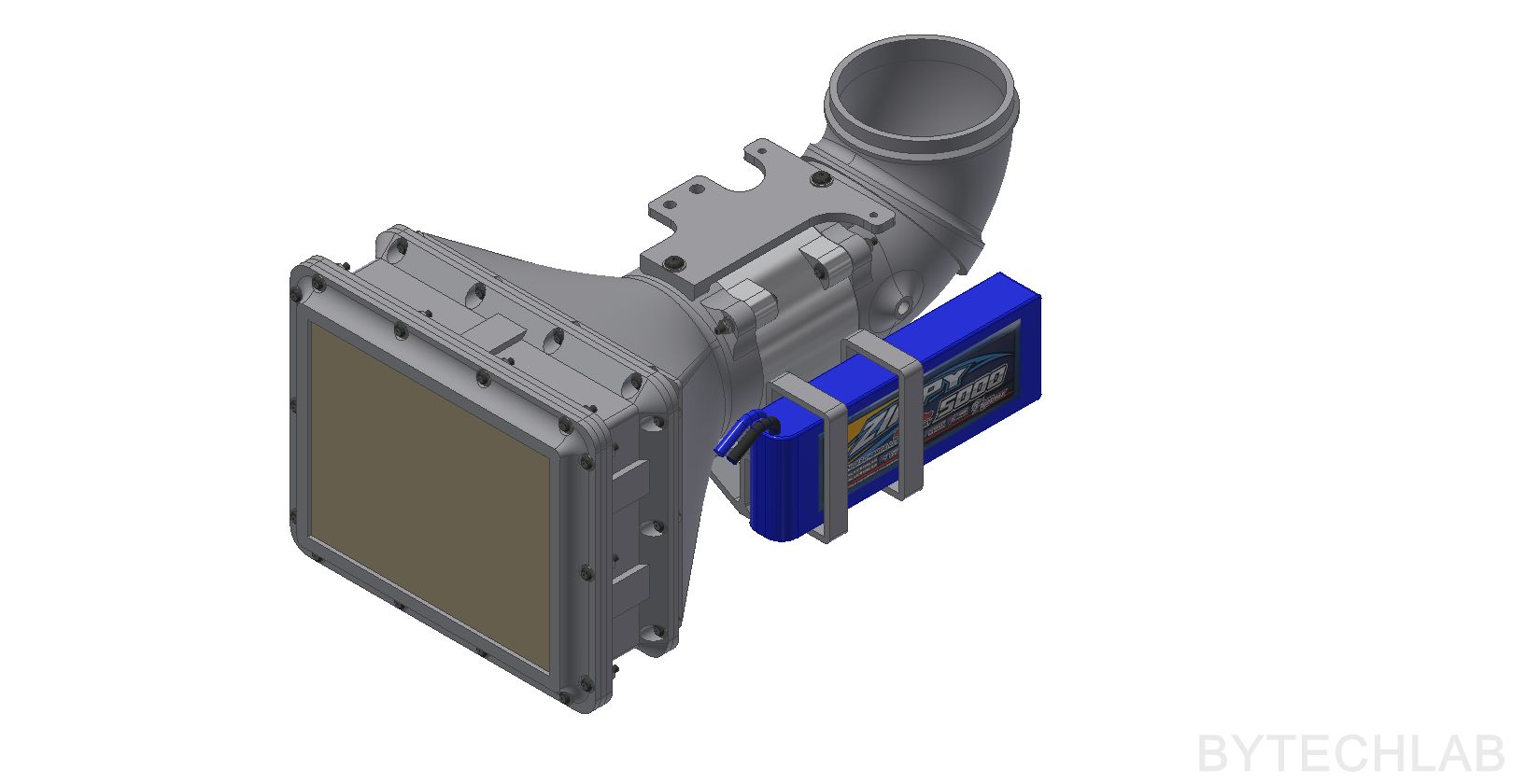

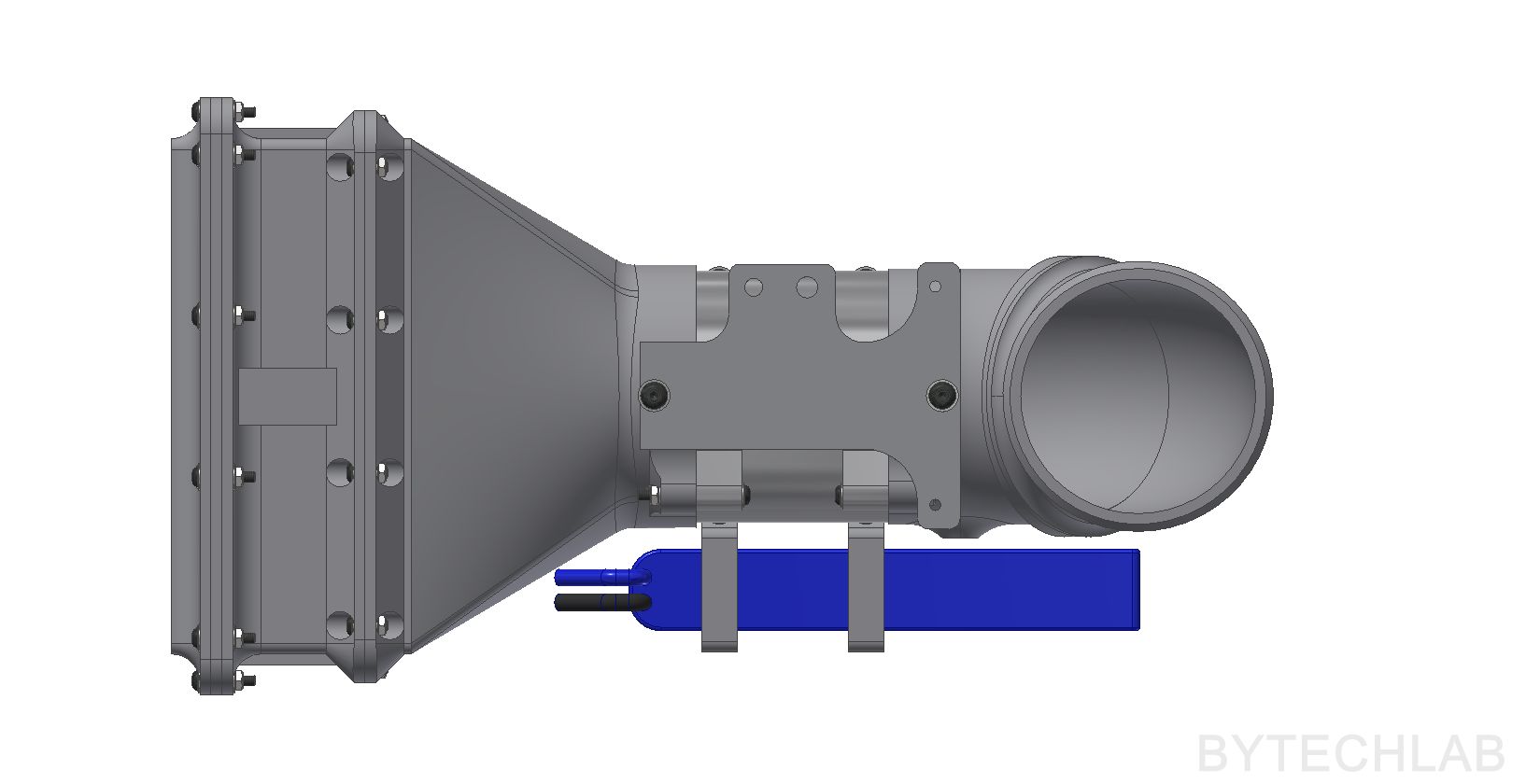

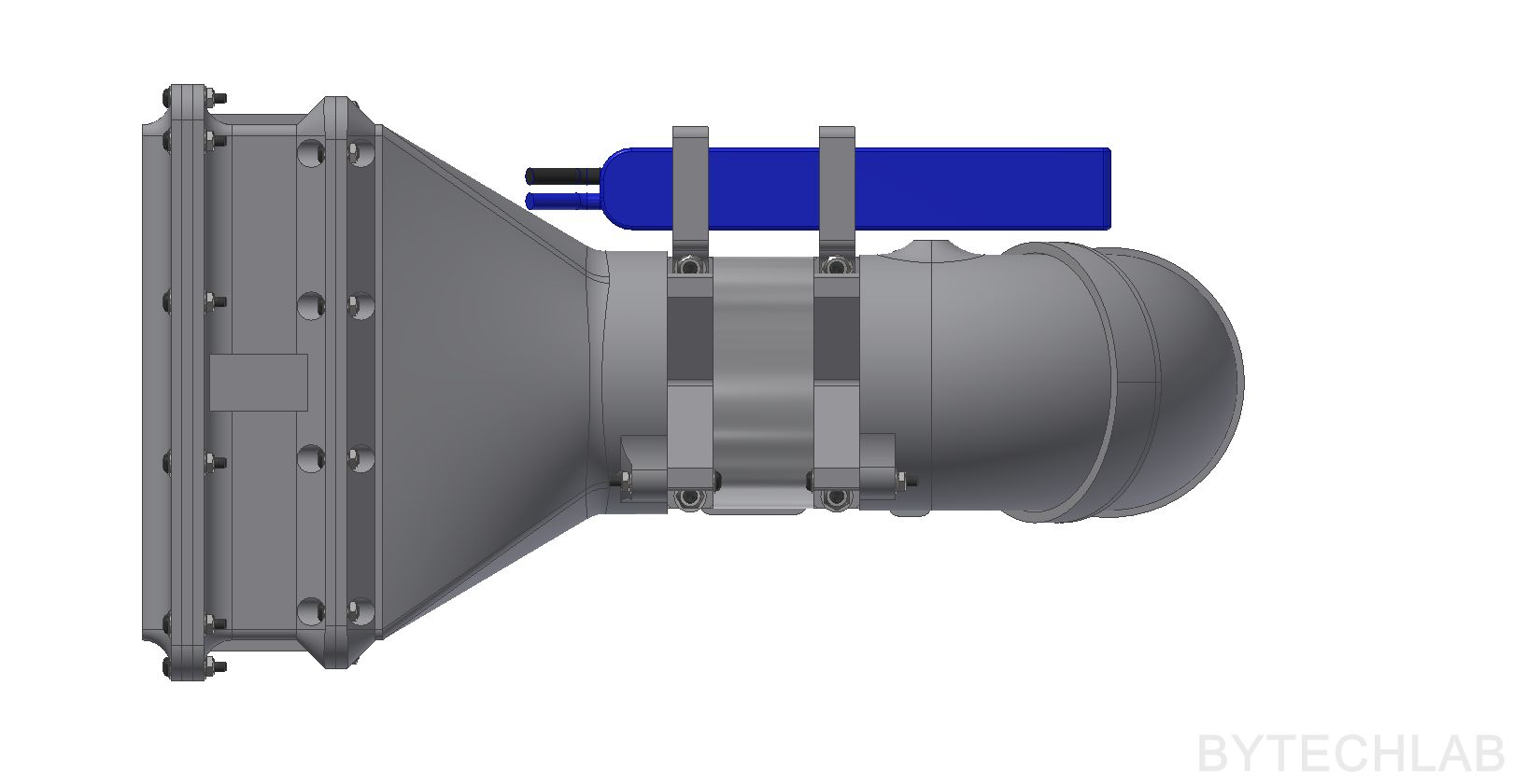

MCAD DESIGN

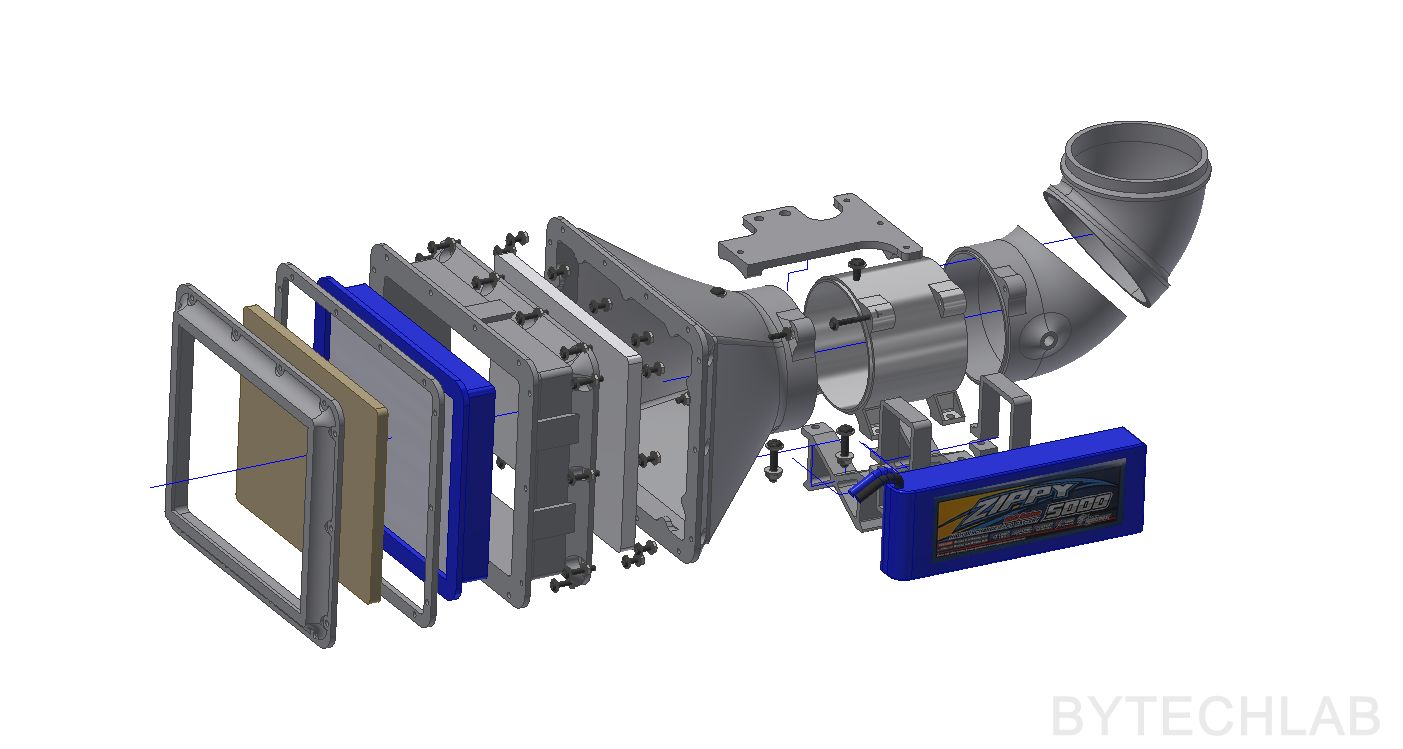

On the drawing above you can see how the air filtering unit for the DIY Positive Pressure Suit is put together. Everything was designed in the way that it can be easily printed on most of the FDM printers (adjusted clearances etc.).

Most of the parts were printed from PETG, ABS and PLA filament.

If you want to redesign some parts or adjust the whole thing to your needs, you can download all CAD files from the links at the bottom of this page.

In the GitHub repository (MCAD folder) you can find the following files:

- Autodesk Inventor project,

- Exported STL files for 3D printing,

- Exported STEP file of the whole assembly,

- Exported PDF file with assembly drawing, BOM and assembly instructions,

- Exported assembly renders,

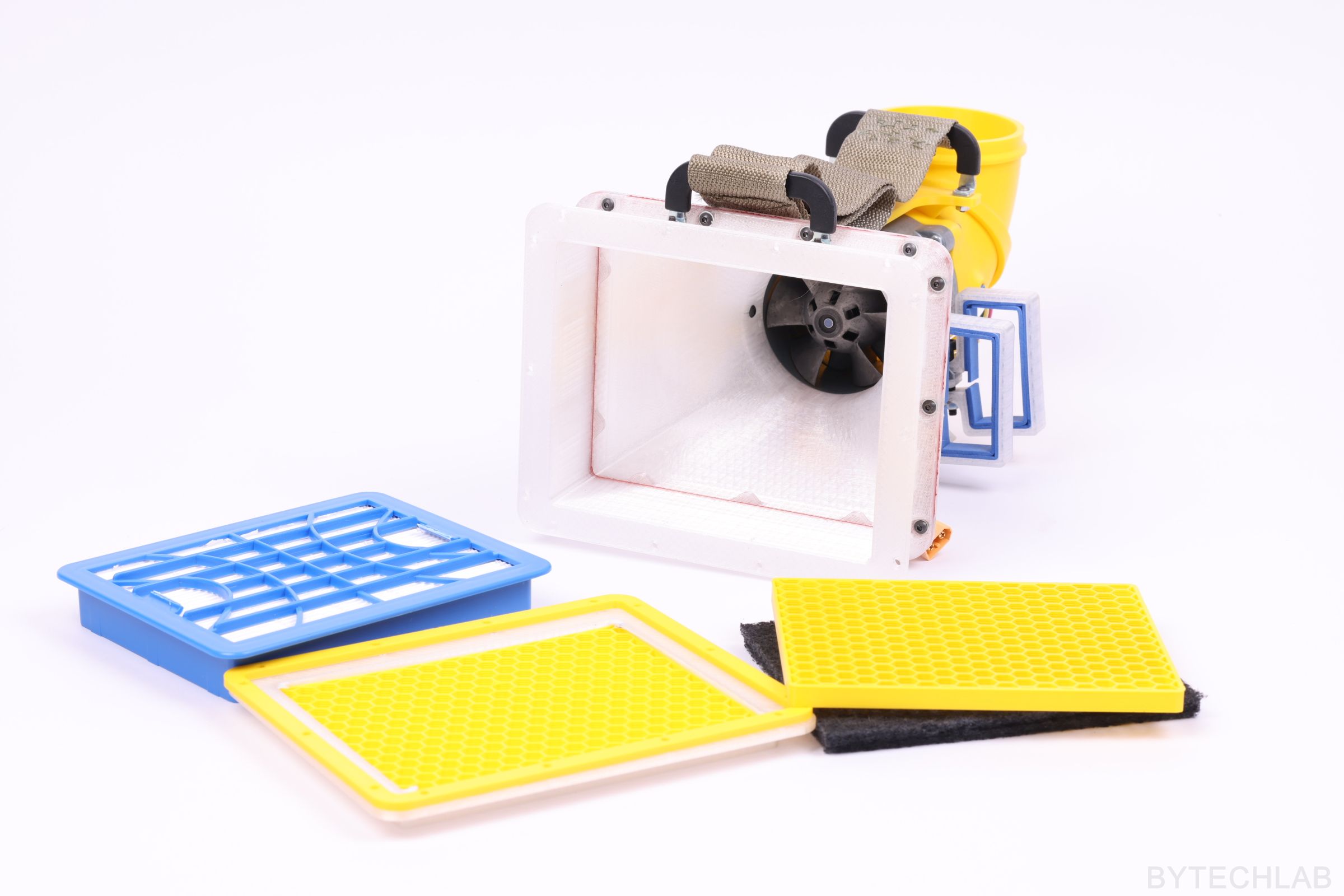

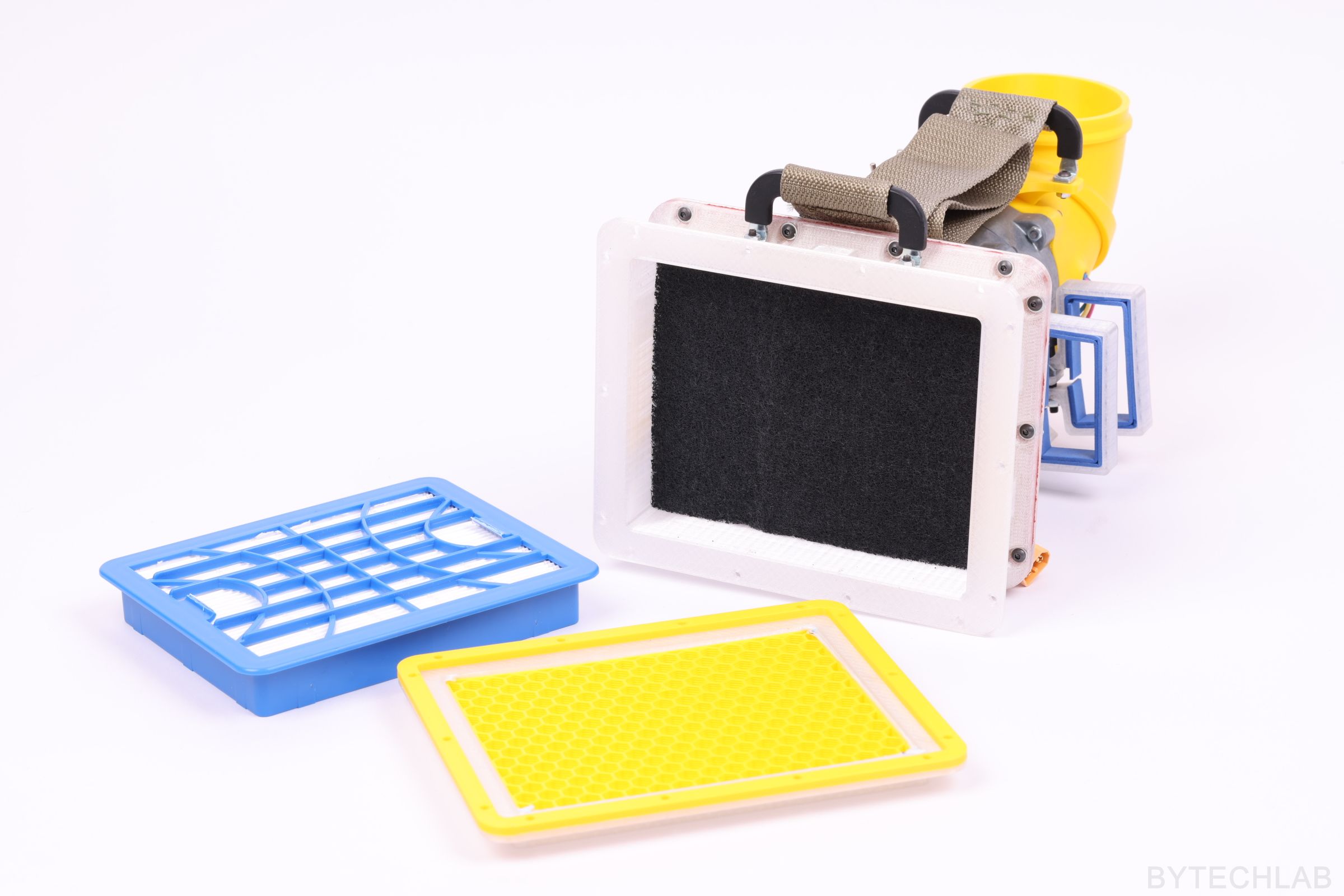

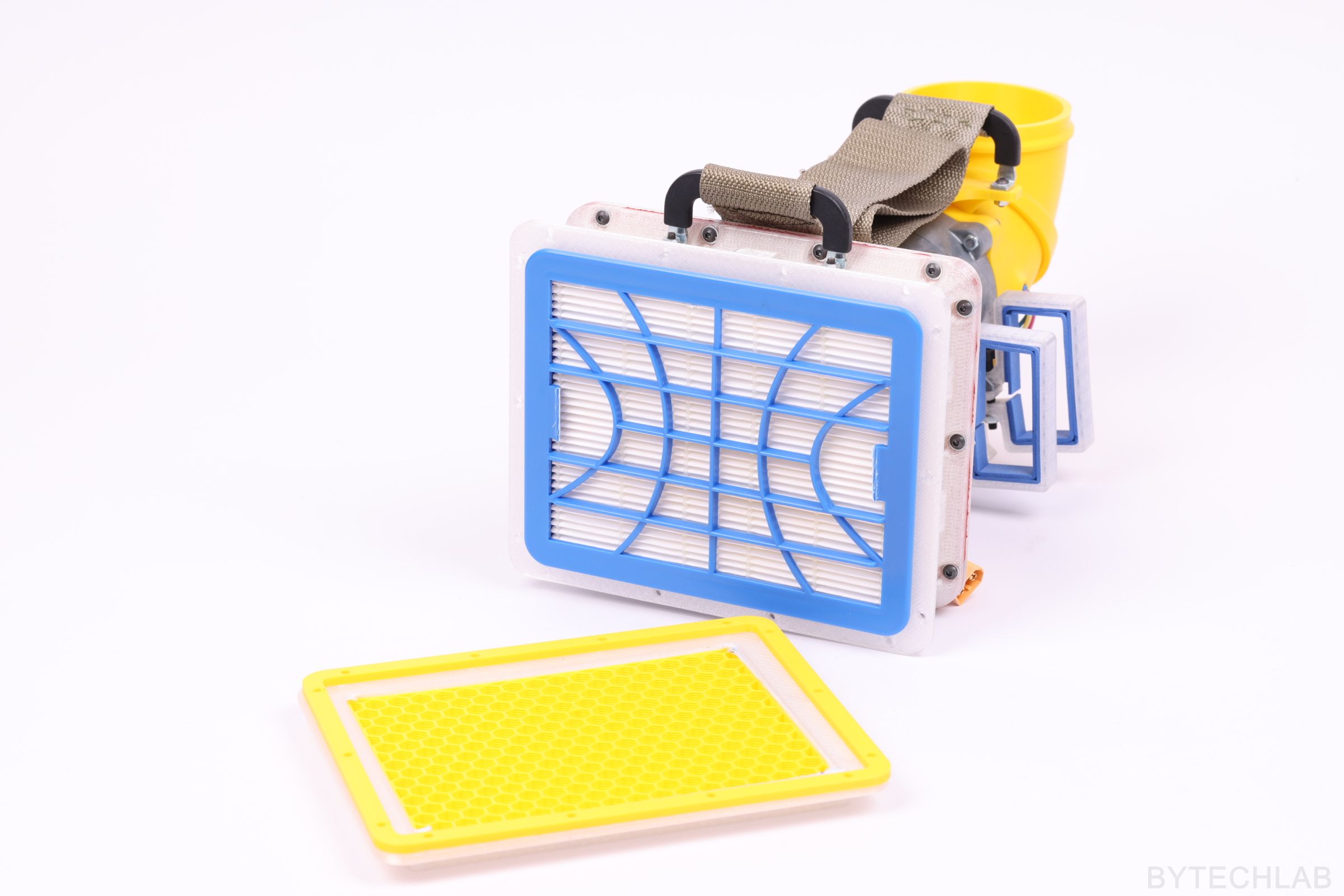

FILTER CHAMBER

The whole thing was designed in the way that filters can be easily swapped. In this prototype I’ve used 3 layers of filters: fabric filter from medical mask, HEPA filter and activated carbon air filter. Because of modular design more layers of filtering stuff can be easily added. So wheres the catch? Well, you can’t add too many filters that restrict air flow too much – the turbine might not have enough power to push air through them to provide sufficient air flow.

You can choose whatever filters you want, the filters that I’ve used are only one of many possible solutions.

Down below you can find some photos of each filtering stage as well as short description.

3 rd stage – activated carbon filters

3 rd stage is made from 3 layers of activated carbon cloth. The purpose of this stage is to catch and absorb everything that might have passed through the first two filters. A fancy honeycomb mesh prevents carbon cloth from being sucked into the turbine. All filters above this stage and below second stage are supported by this structure.

I have also an idea to fill honeycomb mesh with activated carbon particles to add even more layers of filters.

If you want too add more fancy types of filters you can stack them above this stage and below second stage HEPA filter.

2 nd stage – HEPA filter

You can easily find thousands of HEPA filters in different shapes that are intended for use in vacuum cleaners or air purifiers. The filter that I’ve bought was intended for use in vacuum cleaners. This particular filter restricts air flow quite much but I hope that it is able to filter out most of the nasty stuff. It is sealed with a gasket which was included with the filter.

1 st stage – medical mask filtering material

This stage is intended to catch most of the bigger particles. It should be replaced or washed quite often to make sure that nasty particles which contain viruses don’t contaminate and “clog” rest of the filters. It is also supported by a thin honeycomb mesh.

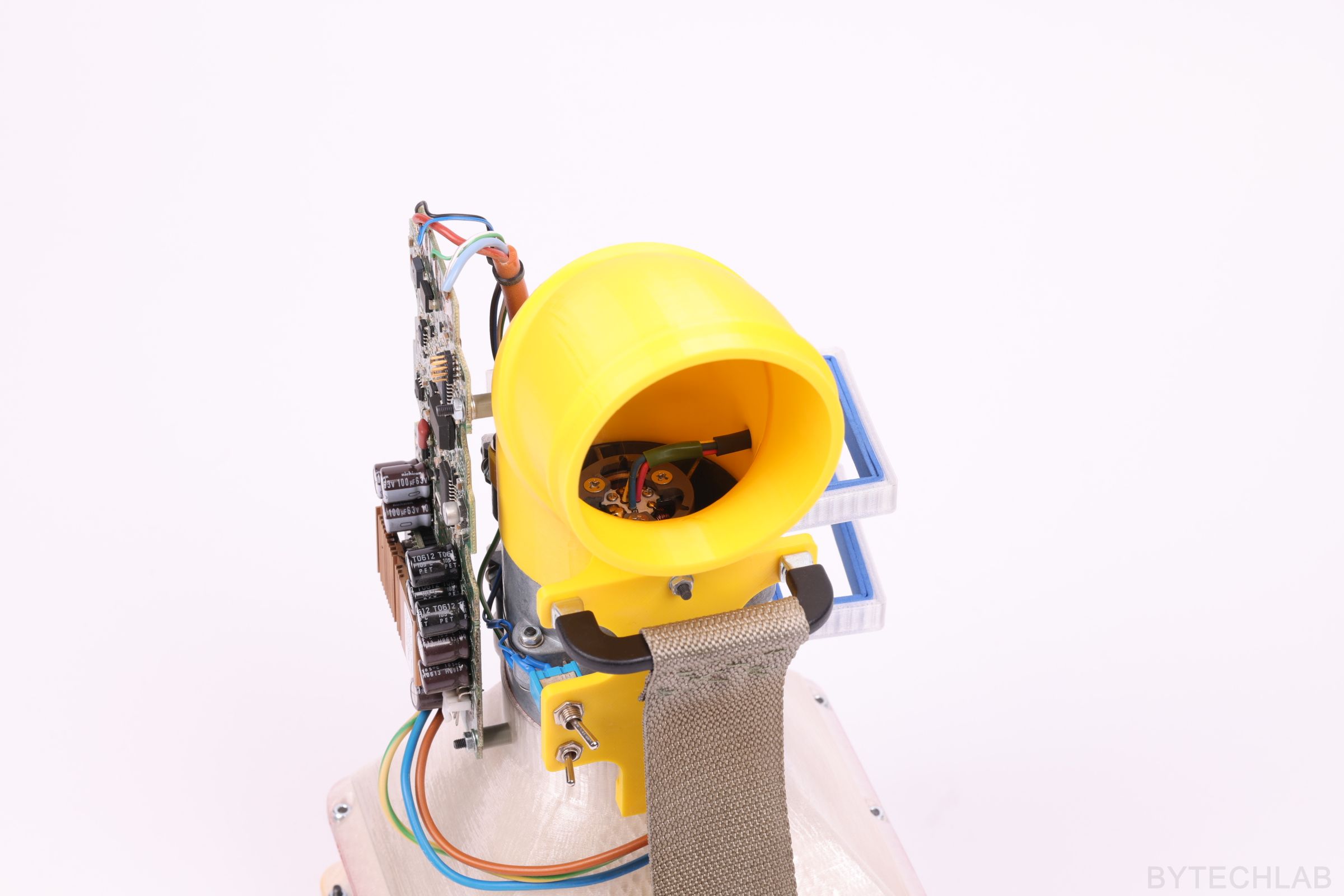

TURBINE

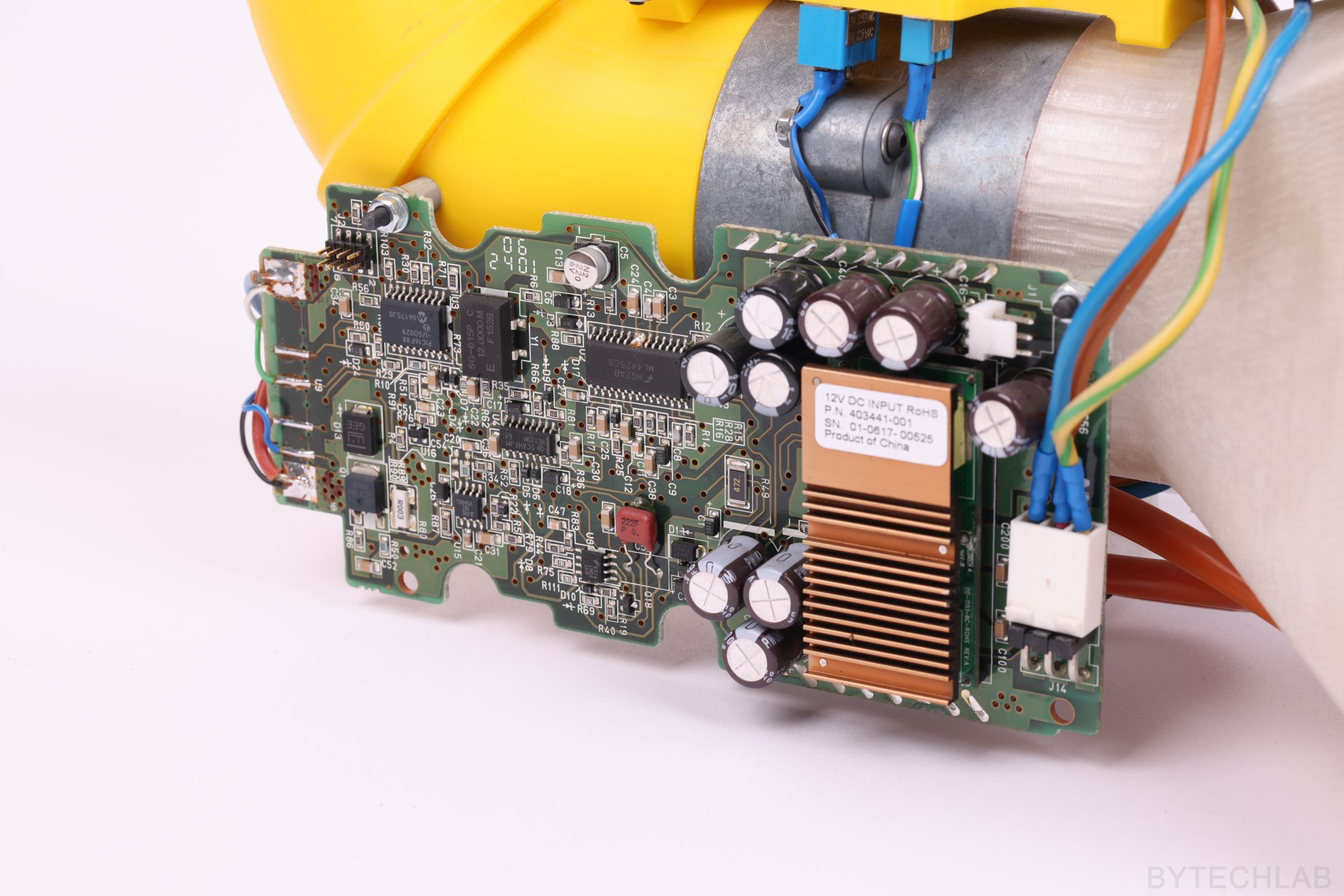

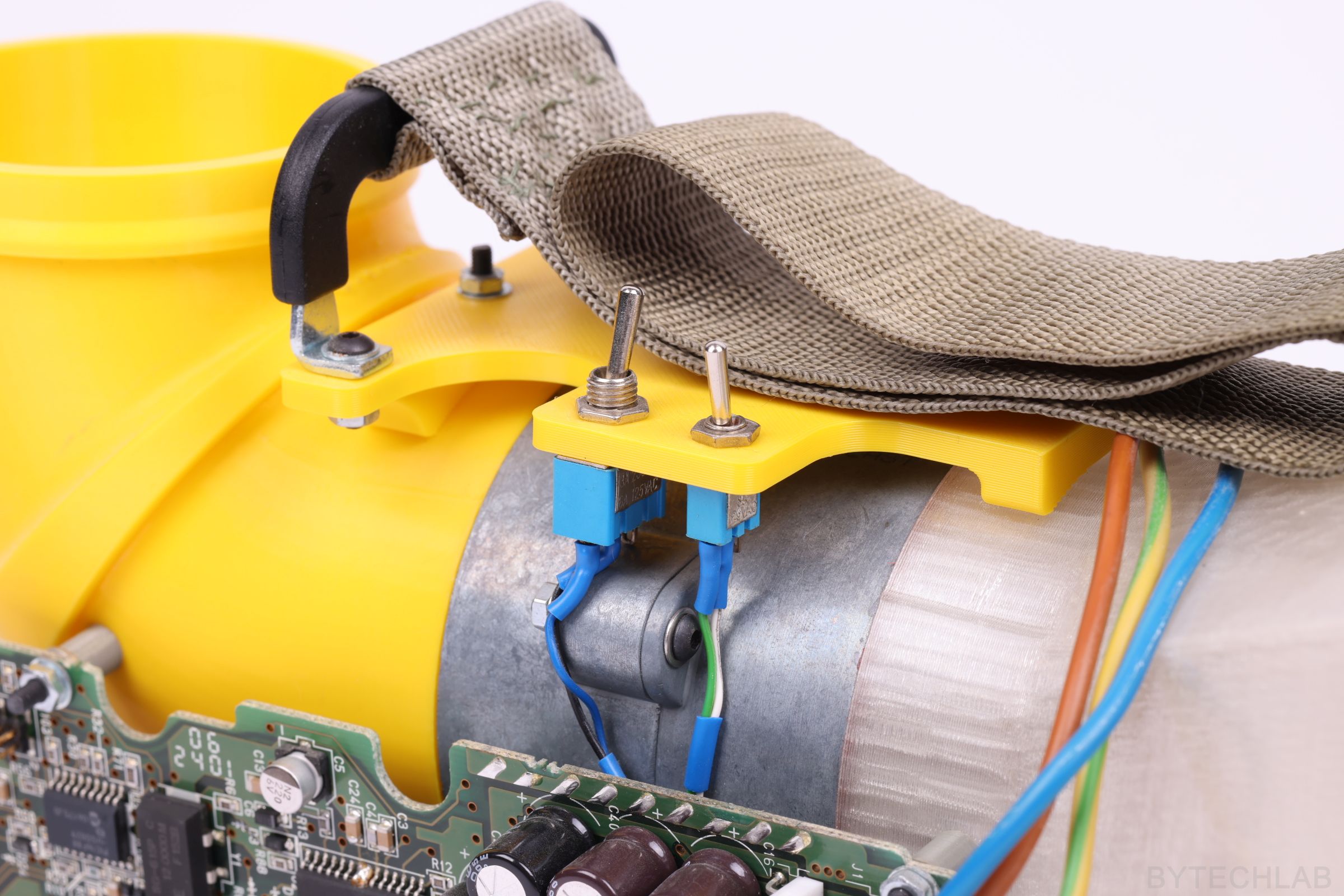

I’ve used a turbine extracted from HP BLC7000 server fan unit. To be honest , I was surprised how powerful this small turbine is (the airflow is more than enough to inflate the DIY Positive Pressure Suit). I think that it is at least as powerful as leaf blower. When it is turned on at full power it is very noisy, it sounds like a mini jet engine. This particular turbine uses a BLDC motor, therefore it needs a driver to function properly. Fortunately, driver PCB that was inside HP BLC7000 fan unit can be easily hacked and reused. I’ve been trying to implement a smooth adjustment of speed, but I haven’t found any simple solution, deeper reverse engineering is required. As it turned out later there actually is a pin responsible for speed control, unfortunately it allows you to set between 2 speeds only (mid and max RPM). I’ve soldered a switch to this pin.

The whole turbine is very well made, it was cast from magnesium alloy. At this price (I’ve paid about 5$/piece at local store) it is a total bargain !

The turbine on max RPM draws approx. 50 – 70 W. I think it is possible to get more “juice” from it by using external ESC.

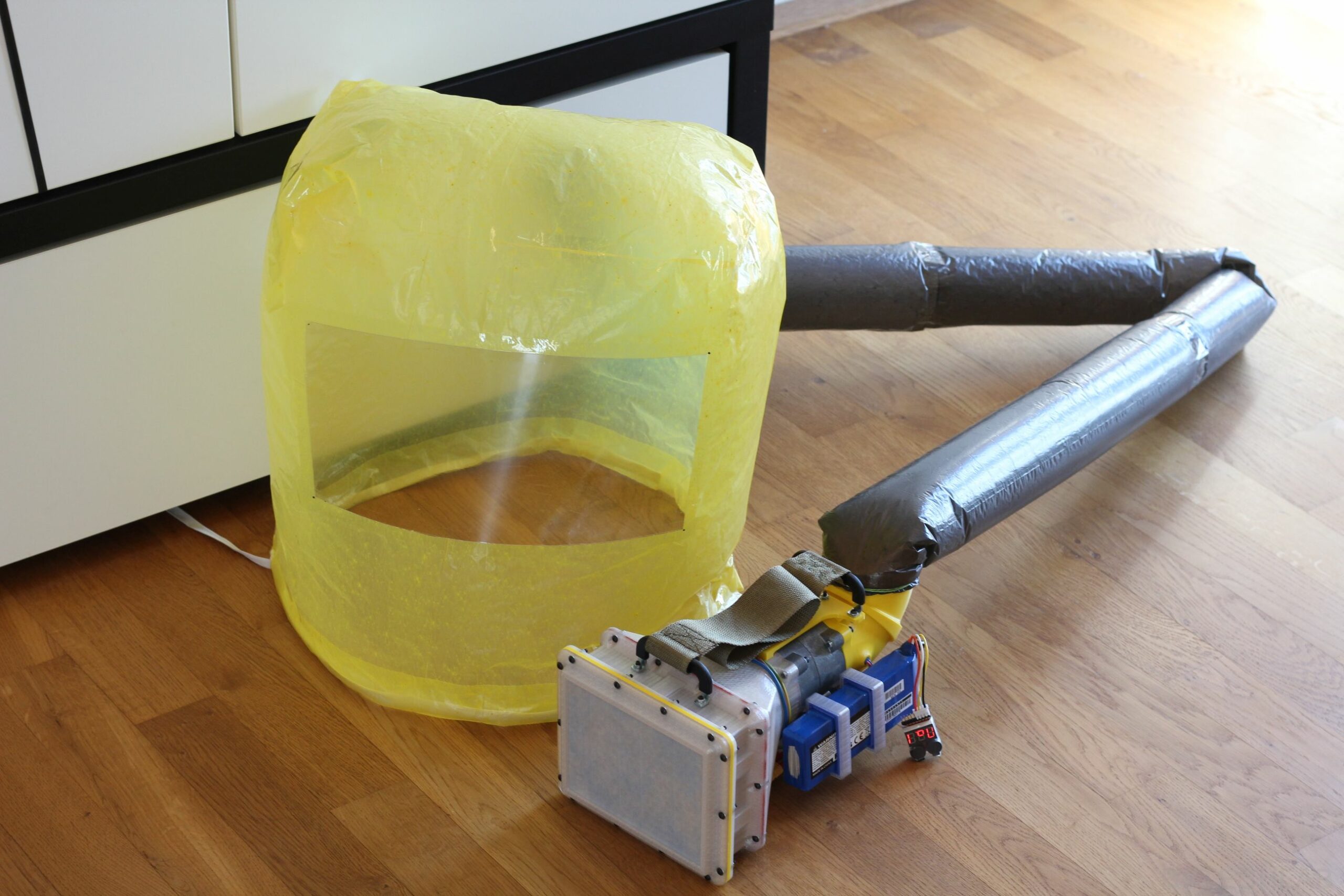

POSITIVE PRESSURE SUIT TESTS

The whole pressure suit will be made from thick trash bags, everything will be cut to size and glued together with adhesive tape. As I mentioned before, it doesn’t have to be 100% leak-proof. For now I’ve made only a helmet with a viewfinder to protect my head which is the most vulnerable part of our body. Fresh air is being pumped by AFU through hose. Air that I breath out is being pushed out through gap around my neck.

MORE PHOTOS

LINKS

- Grabcad: https://grabcad.com/library/covid-19-air-filtering-unit-pressure-suit-1

- Thingiverse: https://www.thingiverse.com/thing:4274445

SUMMARY

I hope that I’ve inspired you with this DIY Positive Pressure Suit to create similar devices which may contribute to stopping spread of COVID-19 virus.

Stay at home, follow the quarantine rules and everything will be fine, we will go through it!